Lightweight Precast EPS Cement Sandwich Concrete Wall Panels Making Machine

Basic Info.

| Model NO. | HFP512A WALL PANEL MACHINE |

| Customized | Customized |

| Automatic Grade | Automatic |

| Type | Hydroforming |

| High Construction Speed | 100m2 Per Worker Per Day |

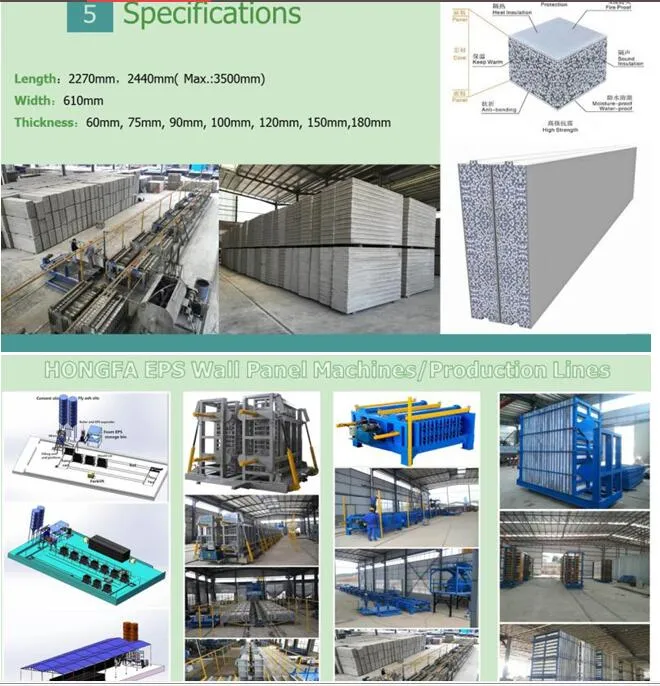

| Advantages of The Cement Wall Panel | Environmental, Fireproof, Light Weight, Soundproof |

| Thickness of The Light Weight Wall Panel | 60mm, 75mm, 90mm, 100mm, 120mm, 150mm |

| Gurantee Period | 3 Year After Delivery |

| Transport Package | Seaworthy Package |

| Specification | 2750*2504*1359mm |

| Trademark | HONGFA |

| Origin | Guangxi, China |

| HS Code | 8474802000 |

| Production Capacity | 50000m2 to 500, 000m2 Per Year |

Packaging & Delivery

Package Size 275.00cm * 250.00cm * 136.00cm Package Gross Weight 5200.000kgProduct Description

lightweight precast eps cement sandwich concrete wall panels making machine

The Production Process of EPS Sandwich Cement Lightweight Wall Panel

EPS sandwich panel machine adopts PLC and touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

The closed constant pressure foaming barrel features of high heating efficiency.

| Item | Unit | EPS light wall panel | ||

| 60mm | 90mm | 120mm | ||

| Anti-impact capacity | time | ≥5 | ≥5 | ≥5 |

| Anti-bending damage load | / | ≥1.5 | ≥1.5 | ≥1.5 |

| Compressive strength | MPa | ≥3.7 | ≥4.0 | ≥4.2 |

| Softening coefficient | / | ≥0.84 | ≥0.84 | ≥0.84 |

| Surface density | kg/m2 | ≤55 | ≤65 | ≤75 |

| Moisture rate | % | ≤1.9 | ≤1.9 | ≤1.9 |

| Hanging force | N | ≥1000 | ≥1000 | ≥1000 |

| Drying shrinkage value | mm/m | ≤0.3 | ≤0.3 | ≤0.3 |

| Heat transfer coefficient | W/(m2·k) | / | / | ≤1.45 |

| Radioactivity limit | / | ≤0.25 | ≤0.25 | ≤0.25 |

| Sound insulation | dB | ≥35 | ≥42 | ≥50 |

| Fire proof limit | h | ≥2 | ≥2.35 | ≥3 |

The Sandwich Lightweight EPS Cement Making Machine Features:The light weight eps concrete machine is equipped with fluidized bed dryer, including drying, automatic sieving, depluming and material conveying to silos.

Most components of eps light weight wall panel making machine are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.

Lightweight EPS Wallboard Making Machine (Horizontal Type) Solve the Following Problems:

The horizontal lightweight EPS wallboard making machine greatly reduces the labor intensity of production workers, and completely removes the disadvantages of the past vertical molds and other molds casting.

Horizon molding wall panel production line to solve problems like aluminum alloy plate loading of other models, not accurate size slurry perfusion pouring, core material not full, need to manually using the steel core and vibration compaction, demoulding time problem. The design concept of science and mature skills production made of domestically the most advanced production equipment and good quality EPS wall plate.

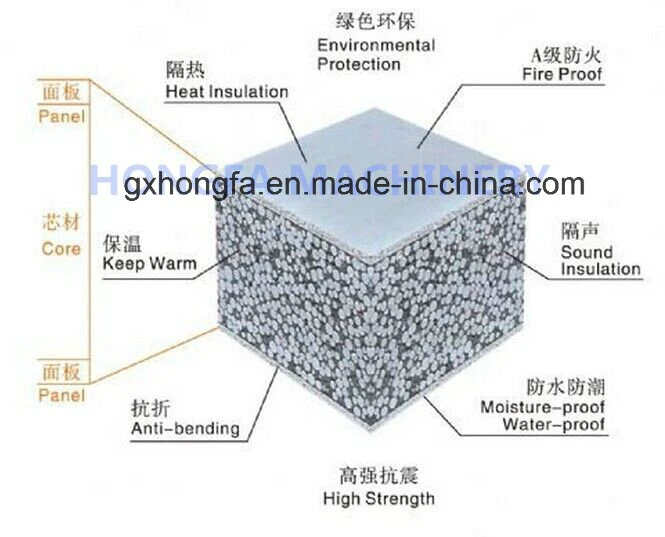

EPS new green wall panel has five features:

(A) Lightweight: The raw materials used are Lightweight aggregates, fly ash,etc, non-reinforced concrete, gravel and other heavy feedstock. So it has the characteristics of lightweight, which is only 1/16 weight of the brick and concrete structure.It can significantly reduce the vertical load of the building structure and reduces building weight and project cost.

(B)Insulation Resistance: As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products.

(C) Permeability Resistance: The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) Fireproof performance: this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

(E) Soundproofing: As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation.

With low business risk for establishing the EPS sandwich wall board machinery.

(A) long-term stability advantages: Due to the limit of functional requirements of the restrictions and sources of raw materials needed to be broad and rich , but also by limiting the requirements of the human environment, the wall construction material development developers is relatively difficult.Once this kind of wall material is successfully developed and is recognized by the government and society,its competitive advantage will be relatively stable and long-term business in the market. (B) Mechanization in production, so less workers but high output and stability.(C) It is a comprehensive utilization of the industrial wastes project, and will get a great support from the Government.

Our Services

The three types of the cement wall board forming machine:

1: Horizontal type EPS wall board forming machine: high level of automatic operation,fewer workers required.

| Horizontal Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 2750x2504x1359 mm | 3kw | 16pcs | 14pcs | 12pcs | 12pcs | 10pcs | 8pcs |

2: Automatic vertical type: automatic operation,high output,fewer workers required.

| Automatic Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3380x3200x2680 mm | 4kw | 40pcs | 36pcs | 32pcs | 30pcs | 26pcs | 22pcs |

3: Manual vertical type partition wall board making machine: Manual operation,the highest output amount the three types, but requires more workers.

| Manual Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3600x1320x2800 mm | no | 58pcs | 50pcs | 42pcs | 40pcs | 34pcs | 28pcs |

Successful Plant

FAQ

Shipping port: Qingdao or Fangcheng Port China.Payment:30% as down deposit by T/T ,70% as the balance paid before loading Guarantee Period: Three year after installation finished at buyer's factory.The above price includes one mold for free, extra molds should be paid according to design.The video is available to send to you, please contact me.

Package & Delivery

Packing: Naked packing or stretch film packing or according to customers' requirementsDelivery time: Within 40 days after receipt of deposit and moulds confirmation from buyer

After sale service

Guarantee for three year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning. We will provide you with a set of spare parts for free!

Guangxi Hongfa Heavy Machinery Group Is Your Best Choose

Guangxi Hongfa Heavy Machinery Group was established in 1990, is one of the largest block making manufacturer and leading supplier of the building block industry in China,as an ISO9001-2000 certificate and "Famous Brand in Guangxi"enterprise and member of China Building Block Association.

Hongfa Machinery'Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry2.China National Enterprice Abiding By Contract & Keeping Good Faith3.Quality and Credibility of the Dual-protectionb Demonstration Unit4.High and New Technology Enterprise5.Famous Trademark of China6.Star Enterprise with China Patent7.AAA Grade Credit Enterprise8.Consumer Satisfaction Unit9.One of Top 100 building Material Industry Brands of China10.One of Top Ten Good Faith Units11.Advanced Exporter in Guangxi Province12.Advance Quality Management Unit

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 96 countries and regions, deeply welcomed by clients from all around the world.

Hongfa Machinery Group Main Products :

Concrete mixing plant,mixer,EPS wall panel machine,AAC block production line,concrete block making machine,concrete tile making machine and concrete pipe making machine .

Automatic Block Making:QT12-15D QT12-15 QT10-15D QT10-15 QT9-15 QT8-15D QT8-15B QT6-15D QT6-15C QT6-15B QT4-15D QT4-15C QT4-15B QT4-20C QTJ4-25Semi-automatic:QTJ4-35B2 QTJ4-40B2Semi-automatic egg-laying machine:QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A Color Paver Color tile forming machine:QT3-20 SMY8-150HF-800 pipe-making machine HF-2000 pipe-making machineConcrete Mixing Plant:HZS25 HZS35 HZS50 HZS60 HZS seriesAAC Block production line : 50000~300000M3/Year

When you plan to purchase a certain machine, suggesting to take care below points:

1. What is the brand? ( Now a lot companies embezzle our brand, pls take note our prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market?(we got good reputation and are the biggest supplier in China)

3. What is the materials they used? Manganese steel or A3 steel? (We use Manganese steel which stronger than A3 steel)

4.The price cover to what equipment?( please refer to our quotation list)

5.How can you guarantee the production quality ?

Our production quality follow China construction machinery standard JGJ33-2012. We have more than 30 years experience on producing the machines and will be inspected by QC team for each shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection acceptable.

Please not hesitate to contact us if you are interested in any kinds of products.Contact Information:

Foreign Trade Dept. :Wendy DengGuangxi Hongfa Heavy Machinery Co.,Ltd.Wesite:http://gxhongfa.en.made-in-china.comTel:0086-17776611790 0086-771-5672282 0086-771-6036912Fax: 0086-771-6036901Factory add: Linyi city, Shandong province & Nanning city, Guangxi Province, China