Fully Automatic Thermal Insulation Fireproof Calcium Silicate Board Production Line

Basic Info.

| Model NO. | WX-CS |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Application | Making Gypsum Board |

| Usage | for Indoors Decoration |

| Product Name | Calcium Silicate Board Machine |

| Configuration | Top |

| Advantage | Easy to Operate |

| Transport Package | Suitable for Long Distance Transportation |

| Trademark | wuxing |

| Origin | China |

| HS Code | 84748090 |

| Production Capacity | 5-6 Sets Per Year |

Product Description

Product Description

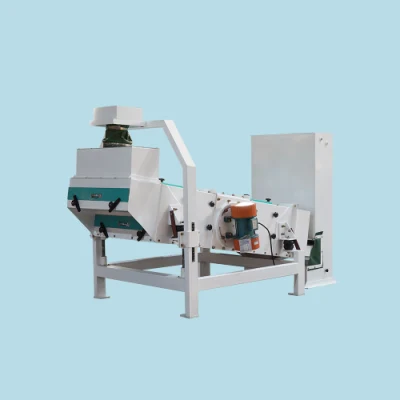

Calcium silicate board is a new type of building decoration material, which is mainly made from high-grade siliceous materials and lime refractory with the mixture of natural fiber as reinforcing material.Slurry preparation sectionIt is composed of raw material tank, pulse single dust collector, screw conveyor, 2m3 dry powder metering tank, water metering tank, mixing pulping machine, returning water tank, mixing device for returning water tank, sedimentation tank and other equipment.Autoclave curing and removal section

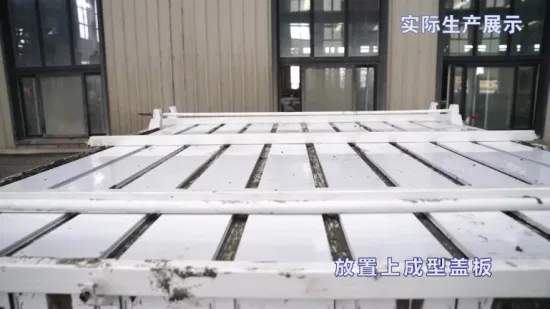

By φ2×21.5m autoclave, three station vacuum stack removal machine, lifting platform and other equipment. Pre feeding and demoulding section

It is composed of electric transversal ferry (before maintenance ), pre-conditioning room, electric transversal ferry (after maintenance), four-station vacuum demouldiing machine, shear lifting platform, mould cleaning brush oil machine and other equipment. Drying section

Dryer conveying equipment.Environmental protection equipment and heating

It is composed of screw air compressor,electronic pulse dust collector, natural gas steam boiler and other equipment.

Product Parameters

1.Fuel: natural gas,coal,heavy oil or diesel.2.Main material: cement,fiber;

Silica sand,cement,fiber;

Silica sand,lime,fiber;

3.Standard product size:

Length:2400-2440 mm

Width: 1200-1220 mm

Thickness: 4-30 mm

Packaging & Shipping

1. Suitable for long distance transportation 2. Small or key parts loaded in iron boxes 3. Iron boxes with welding 4. Naked 5. Please mark it in the sales contract for special package

Detailed Photos

Main Features

1) Product is in accordance with national standard Reinforced Fiber Calcium Silicate Board JC/T564- 2000 of China Material cement, glass fiber, paper pulp, quartz sand,calcium oxide.

2) Density: ≤ 1.5g/cm2 without press > 1.5g/cm2 with press

3) Rupture strength: 15-28 Mpa

4) Thickness: 2-30 mm

5) Panel size: 1220*2440*T(2-30) mm

6) Thermal conductive index: 0.24W/MK(JC/T54)

7) Moisture content: ≤ 10%

8)Water absorption rate:19%

9) Water consumption: 450m3/day

10)Steam construction: 2.0 ton/hour

Company Profile

* The predecessor is stated-owned enterprice,was built in the 1970s.* A large manufacturer of integrated supply dedicated in researching,manufacturing, trading of building material machinery and construction materials .* CE approved by the EU * ISO 9001 certificate *We have professional team and rich experience.* We provide perfect after-sales service to solve customers' worries.

FAQ

1

Q:Are you a factory or trading company?

A:We are a factory.

2

Q:Where is your factory located? A:Our factory is located in Shijiazhuang, Hebei Province, China. All our clients, from home or abroad, are warmly welcome to visit us!

3

Q:How can I know more about the product?

A: We are honored to send you some pictures and videos about our product. And we welcome every customer visit our factory.

4

Q:How does your factory do regarding quality control?

A:Quality is priority. Factory director always attach great importance to quality controlling from the beginning to the end. Our factory has gained CE and ISO9001 authentication.

If you have any doubt, pls contact me. Lucy Dong