Paint Machine Box Feed Powder Coating Equipment/Machine Powder Spraying Machine K1y

Basic Info.

| Model NO. | K1YB |

| Application | Hardware Spraying Equipment, Wood Spraying Equipment, Plastic Spraying Equipment, Porcelain Spraying Equipment |

| Coating | Powder |

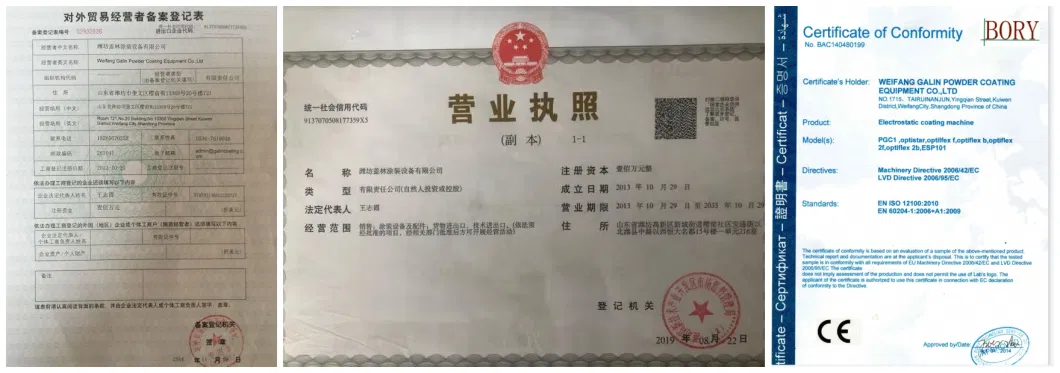

| Certification | CE, ISO |

| Method Type | Manual |

| Condition | New |

| Used for | Mental Sureface |

| Brand | Litone |

| Advantage | Convenient |

| Keywords | Powder Coating Room |

| Operation | Manual |

| Weight | 42kg |

| Frenceny | 50-60Hz |

| Voltage | 220V (110V-240V) |

| Spraying Guns | Manual Gun |

| Usage | Powder Coating Work Pieces |

| Technology | Electrostatic Powder Spraying Technology |

| Kinds of Coating | Powder |

| Color | Photo Color |

| Package | Carton /Wooden Box |

| Product Name | Powder Coating Machine |

| Transport Package | Carton&Wooden Box |

| Specification | STANDARD |

| Trademark | LITONE |

| Origin | China Shangdong |

| HS Code | 8424300000 |

| Production Capacity | 100/Month |

Packaging & Delivery

Package Size 14.00cm * 15.00cm * 17.00cm Package Gross Weight 1.000kgProduct Description

Powder coating machine K1Y-B

Field of applicationThe application range of electrostatic spraying is expanding day by day, from large railway passenger cars, automobiles, tractors, to small workpieces, toys and household appliances and other industries, electrostatic spraying technology can be usedPowder coating machine - overview

Electrostatic powder coating is a spraying method in which the atomized paint is negatively charged by a high-voltage direct current electric field and adsorbed on the surface of a positively charged substrate for discharge. Electrostatic powder coating equipment consists of a spray gun, a spray cup, and a high-voltage power supply for electrostatic spraying.In the case of electrostatic powder coating in strict accordance with the correct operating procedures, due to the high-voltage electrostatic field, the dispersion of the coating particles is high, and the distribution in the jet is also relatively uniform, so the coating formed on the surface of the sprayed workpiece is also relatively flat and uniform. The gloss and adhesion of the film are also high.Production practice shows that in the electrostatic spraying continuous flow production line, the running speed of the conveyor belt can reach 24m/min, far exceeding other coating production lines. The comprehensive economic effect of electrostatic spraying is particularly obvious for wooden parts such as tables, chairs, frames, etc. that cannot be used for curtain coating or roller coating frame structure.The main disadvantage of electrostatic powder coating is the high risk of fire, especially when spark discharge is caused by improper spraying distance or improper operation, it is easy to cause fire. Therefore, reliable fire-proof and explosion-proof facilities must be provided, and safe operating procedures must be strictly followed. In addition, it is difficult to obtain a uniform coating by electrostatic spraying on surfaces with complex shapes and deep contours.

Advantage:

1.Suitable for changing color frequently2.Proportional valve valve control,gas precision3.LED makes operatation more easier4.Powder charging rate:75%-85%

| Electrical data | Nominal input voltage | 220V (100V-240VAC) |

| Frequency | 50/60 Hz | |

| Rated output voltage (to gun) | 12~18VPP | |

| Rated output Frequency (to gun) | About 20KHZ | |

| Protection type | IP54 | |

| Temperature rang | +10ºC to +40ºC (+50ºF to +104ºF) | |

| Solenoid Valve Volatge | 24VDC | |

| Gun output voltage | 0-100KVDC | |

| Gun output current | 0-100μA | |

| Pneumatical data | MAX.input pressure | 10bar |

| MIN.input pressure | 6bar | |

| Output pressure | 0~10bar | |

| Max.water vapor content of the compressed air | 1.3g/m³ | |

| Max.oil vapor content | 0.1mg/m³ | |

| Max.compressed air consumption | 8 Nm³/h | |

| Gun paramter | Input | 0-15VDC |

| Voltage Frequency | Around 20KHZ | |

| Input Current | <0.5A | |

| Output Voltage | 15~100KV negative | |

| Max.Output powder volume | Around 600G/MIN | |

| Gun cable | 6 M | |

| Gun weight | 425g |

| DIMENSIONS | |

| Size | 460mm*862mm*1105mm |

| Weight | 42kg |

| PNEUMATIC DATA | |

| Min.input pressure (dynamical) | 6bar |

| Max.input pressure | 10bar |

| Max.oil vapor content | 0.1mg/m³ |

| Max.water vopar content | 1.3g/m³ |

| Max.compressed air consumption | 8Nm³/h |

| ELECTRICAL DATA | |

| Input voltage | 220V(100v-240v) |

| Frequency | 50-60Hz |

Packaging:

Paper Carton / Woden box

Shipping:

DHL/UPS/FedEx/EMS,etc

We are a typical Chinese supplier and specialized in the research, development and production of powder coating system and liquid painting system. Our products include the booth, hopper, powder coating machine/unit, electrostatic spray gun, panel controller, cascade, PCB board, powder injector/pump, powder hose, filter and other parts and so on.

In addition, we can make all kinds of cascade, like international brand.

We not only supply the high-quality coating equipment, but also the best service.

If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Our Advantages1. Product technical advantagesOur company has set up a professional team to overcome technical difficulties and develop new products every quarter. The product adopts the latest technology, energy saving and environmental protection, and can be remotely controlled automatically. Ensure that Litone brand products occupy a leading position in the field of market technology, and let agents and distributors take the initiative in the market.2. Advantages of series productsThe company's electrostatic powder spraying machine has high efficiency, energy saving, simple operation, high adsorption force of coating film, and high yield.3. Advantages of new productsThe company attaches great importance to products, constantly develops new products, adds new functions, and develops series of products. New products are launched every quarter to meet the needs of different customers and make consumers willing to spend repeatedly. The richer the product line, the more choices consumers have, and the more opportunities for agents to make money.4. Customized advantage powder coating machineThe company has been focusing on the electrostatic powder coating industry for more than ten years, constantly developing new products, adopting the latest manufacturing technology, and launching a variety of series of products, which can be customized for families, companies, and factories with the functions required by customers.5. The unique advantages of the product powder coating machineThe company independently develops and designs unique PHISRT series products. With unique product functions and appearance, agents can gain a foothold in the local market, enjoy rich returns, and ensure the advantages of stable and sustainable market development. The company is free