Precast Concrete Wall Panel Production Line

Basic Info.

| Model NO. | Customer Request |

| Productivity | 240m²/h |

| Feeding Height | 1400mm |

| Vibrating Amplitude | 2.4mm |

| Certification | ISO9001: 2000, CE |

| Condition | New |

| Color | Blue |

| High-Quality | 100 |

| Transport Package | Sea Transportation |

| Trademark | HAIYU |

| Origin | Shandong, China |

| HS Code | 84748090 |

| Production Capacity | 200 Sets Per Mont |

Product Description

Product Description

Product Description

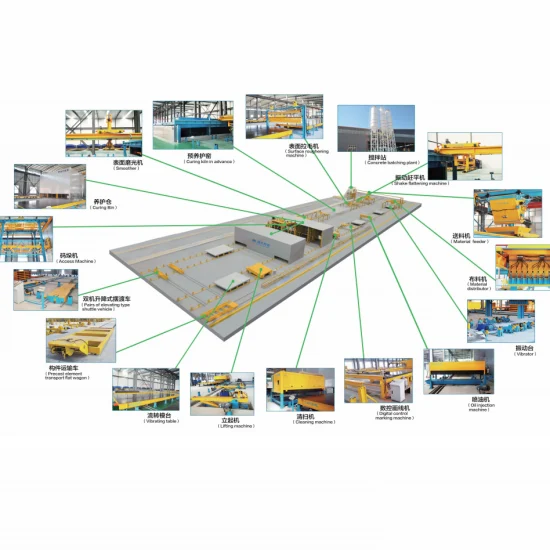

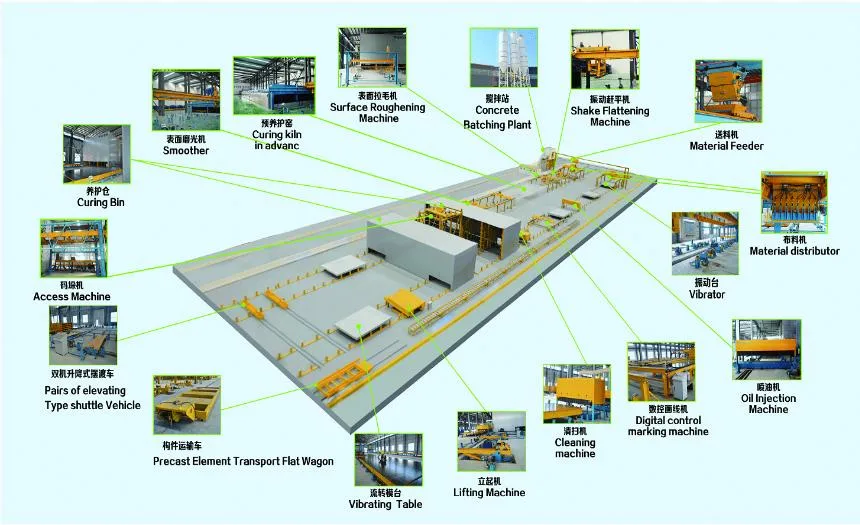

Carousel plant precast concrete production line for walls and slabs

The carousel plant is utilized for producing panel components, including wall panels and floor slabs with a thickness of less than 450 mm. This includes sandwich walls, double walls, solid walls, laminated slabs, lattice girder floors, and more complex or pre-buried wall panels. We can customize our production to meet the specific demands of our customers.Our production line consists of various systems such as concrete conveyance system, feeding system, circulatory system, pretreatment system, curing system,demoulding system,and central control system. The equipment included in this process are tables (with ground walking wheel and table driving wheel), inductive collision avoidance device(s), concrete feeding machine(s), vibration table(s), curing kiln(s), table withdraw machine(s), pre-curing systems hydraulic lifting systems transportation car(s) shuttle bus(es) grinding machines surface texturing machines vibration smoothing machines cleaner(s) oiler numerical control machine and concrete delivery systerm etc.Please refer to the detailed photos provided below for a better understanding of our production process.

Company IntroductionDezhou Haitian Electromechanical Technology Co., Ltd., founded in 1997, is a high-tech enterprise specializing in the construction of industrial intelligent equipment manufacturing, with mature equipment research and development, manufacturing and service experience. Its products are sold all over the country and exported to more than 80 countries and regions. The company is located in No. 956, Hongdu Road, Songguantun Street, Tianqu New District, Dezhou, with a registered capital of 52,040,800 yuan, covers an area of 73 mu and a factory area of more than 30,000 square meters. It has more than 240 employees, including more than 60 R&D technicians, 4 foreign experts and more than 30 senior and intermediate titles. Echelon of R & D technicians can tailor a variety of prefabricated building components and equipment for customers overall solutions, R & D design ability is the core competitiveness of the company. In 2017, the company and China Academy of Building Science jointly undertook the national 13th Five-Year Key research and development Plan green building and construction industrialization key special project "Key technology and assembly of Precast concrete component industrial production" (project number: 2017YFC0704000), the scientific research achievements identified as the international leading technology. The company has edited 3 national industry standards and participated in 11 national standards. The company has more than 100 patents, including 36 invention patents (11 have been authorized).

Welcome to visit our plant!

1.Why choose you?

-26 years professional experiences in the precast concrete machinery/molds and production line.

-Vice president of CCPA(Short for "Concrete and Cement Products Association of China")

-An ISO9001:2008 and CE certified company!

2.Where is your company situated?

Our factory located at Dezhou city, Shandong province, China.

3.How do we come to your factory?

If you are in Shanghai, take fast train from Hongqiao to Dezhou East, it takes 3-4h. If you are in Beijing, take fast train from Beijing South to Dezhou East, it takes 1.5h.We will pick you up at the destination station.

4.What is your payment term ?

You can transfer the payment via T/T. We will provide you the bank detail.

Generally, 30% prepaid and the rest 70% should be paid before shipping.