China CE Approved Tangchen According to Design Precast Concrete Production Line

Basic Info.

| Model NO. | Tangchen |

| Productivity | 90-120 Days/Project |

| Feeding Height | OEM |

| Vibrating Amplitude | Adjustable |

| Certification | ISO9001: 2000, CE, BV |

| Condition | New |

| Color | According to Coating |

| Trade Terms | Ex Works/Fob/CIF |

| Technological Advantage | Our Engineer Is Highly Educated and Experienced |

| Delivery Time | 45 Working Days |

| Power | 380V/50Hz Three-Phase Power Supply |

| Scope of Application | Production of Concrete Spun Pile |

| Transport Package | as Per The Standard Export Packing, Sea Worthy PAC |

| Specification | according to design |

| Trademark | Tangchen |

| Origin | China |

| HS Code | 8480600000 |

| Production Capacity | 3-6 Months |

Product Description

Jiangsu Tang Chen Machinery Equipments Manufacturing Co., Ltd. is Founded in 2011 with registed capital of 25,000,000 CNY, covering a total area of 13.34 hectare including 43000 square meter workshop.

The company mainly focuses on the R&D, production and sales of the mould & equipment for precast concrete elements, especially for concrete spun pile and spun pole.

Instead of only supplying machinery, we provide integrated solution with value added service, so that customers can easily start production by simply turning the key.

Currently the company have exported to Korea, Vietnam, Malaysia, Bangladesh, Cambodia and Indonesia. And have successfully built more than 10 overseas projects.

We are confident we will always be the right choice for you!

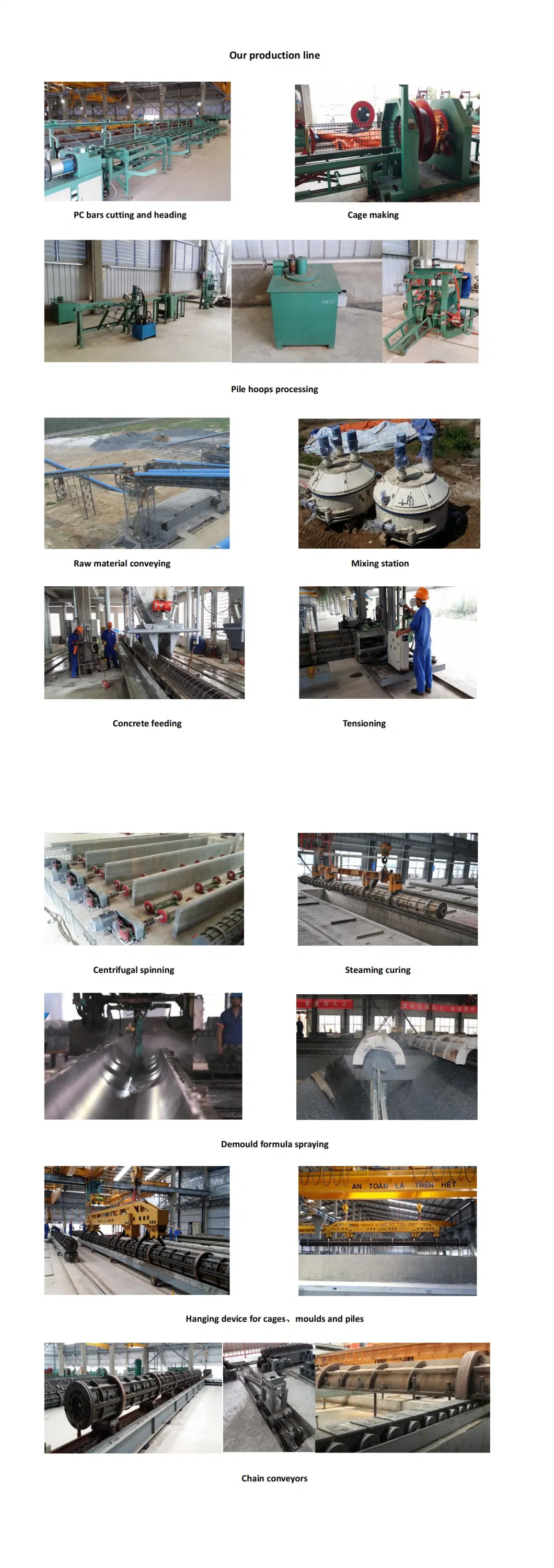

Tangchen can provide profecssional concrete production line.

| step 1 | raw material mixing & steel bar cage making |

| step 2 | cage placing & concrete feeding |

| step 3 | stressing |

| step 4 | centrifugal spinning |

| step 5 | steam curing |

| step 6 | demoulding |

| step 7 | high pressure curing |

Tang Chen Machinery is one of the very few Manufacturers in China that can supply complete set of highly automatic production line of prestressed concrete electric utility pole. Compared to traditional electric pole production line, this production line has made the manufacturing of electric pole less human-dependent. That means higher efficency and lower failure rate.

The production line is consist of 6 major parts: 1. Raw material mixing system, 2.Steel cage making system, 3. Concrete feeding and placing system, 4. Centrifugal shaping system, 5. Conveyor system, 6. Hanging and spread system.