Dust Cleaning Machine Cleaner Laser Machine Price

Overview Package Size 105.00cm * 50.00cm * 75.00cm Package Gross Weight 95.000kg Laser Cleaning Machine PRODUCT APPLICAT

Overview

It can be applied to industry rust removal with high efficiency, by using CW laser cleaning.

1. For aerospace industry: cleaning before and after aluminum alloy welding; cleaning of titanium alloy before and after welding; Aircraft radar layer repair laser cleaning.2. For shipbuilding industry: laser cleaning before and after welding in shipbuilding; Laser cleaning of surface before coating; Ship maintenance training.3. For rail transit industry: stainless steel train manufacturing and cleaning; Aluminum alloy train manufacturing laser cleaning; Rail transit equipment maintenance and laser cleaning.4. For automobile manufacturing industry: cleaning of galvanized sheet before welding; Cleaning of Al alloy before and after welding.5. For steel manufacturing industry: derusting of steel surface; derusting of cold rolled sheet surface.TECHNICAL PARAMETER

Basic Info.

| Model NO. | HY-CR01 |

| Warranty | 2 Years Laser Source |

| Cleaning Spot Size | 10-110mm |

| Scan Speed | 10-7000mm/S |

| Size | W/L/H(90*38*60cm) |

| Scanning System | Galvanometer Scanning System |

| Cooling Method | Air Cooling |

| Overall Power | 400W |

| Max Power | 200W |

| Laser Source | Gz/Jpt |

| Focal Length | Focal Length of Field Mirror |

| Pulse Width | 1-500ns |

| Transport Package | Ocean Shipping |

| Specification | 120KG |

| Trademark | HAIYI Laser |

| Origin | Jiangsu/China |

| HS Code | 8479899990 |

| Production Capacity | 500sets/Year |

Packaging & Delivery

Package Size 105.00cm * 50.00cm * 75.00cm Package Gross Weight 95.000kgProduct Description

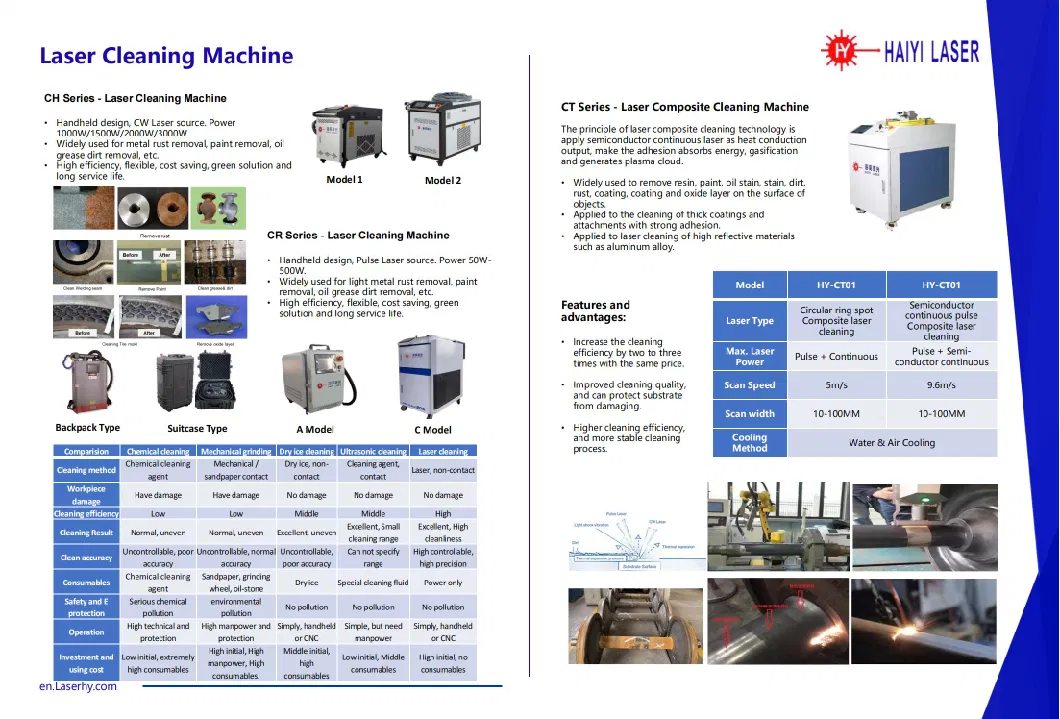

Laser Cleaning Machine

PRODUCT

It can be applied to industry rust removal with high efficiency, by using CW laser cleaning.

1. For aerospace industry: cleaning before and after aluminum alloy welding; cleaning of titanium alloy before and after welding; Aircraft radar layer repair laser cleaning.2. For shipbuilding industry: laser cleaning before and after welding in shipbuilding; Laser cleaning of surface before coating; Ship maintenance training.3. For rail transit industry: stainless steel train manufacturing and cleaning; Aluminum alloy train manufacturing laser cleaning; Rail transit equipment maintenance and laser cleaning.4. For automobile manufacturing industry: cleaning of galvanized sheet before welding; Cleaning of Al alloy before and after welding.5. For steel manufacturing industry: derusting of steel surface; derusting of cold rolled sheet surface.TECHNICAL PARAMETER

| Model | HY-CR01 | HY-CR01 | ||

| Laser Type | Pulse laser source | Pulse laser source | ||

| Max laser power | 50W/100W | 200W | 200W | 300W/500W |

| Scanning spped | 6000mm/s | 10-7000mm/s | ||

| Max scanning width | 10-100mm | 10-120mm | 10-120mm | |

| Cleaning efficiency | 0.2-0.5m2/min | 0.2-0.5m2/min | ||

| Cooling system | Air cooling | Water chiller | ||

| Power supply | 220V/50HZ/60HZ | 220V/50HZ/60HZ | ||

| Size | 62*47*30cm | 90*38*60cm | 90*87*100cm | 90*87*100cm |

| Weight(net) | 28kg | 80kg | 260kg | 270kg |

1.Non contact cleaning will not damage the part matrix. No chemical cleaning solution, no consumables, safe and environmental protection.2.The laser cleaning head is lightweight and can be held for a long time. The laser cleaning system is stable and almost maintenance free.3.High cleaning efficiency and time saving. Red light assists in focusing, and the focusing position can be adjusted according to different field mirrors.4.Precise cleaning, which can realize selective cleaning in precise position and size.5.Easy to operate just powered on. Optional for hand-held and automatic cleaning.

ABOUT US

Q1. How to select the suitable machine?

Tell us your material, detail requirements by words, pictures or video.We will recommend you the suitable model with the reasonable price.Q2. How about the lead time?For the standard machine, the delivery time is 3-7 days after the payment.For the non-standard machine, the delivery time is 7-15 days after the payment.Q3. How to install and use it?We have the instruction Book, Operational manual and Training Video inside the machine.We also can provide the training on line by free.Q4. How to do it if we meet the issue during the operation?You can send the wrong information to us by mail, we can help us solve it by mail.phone, or video communication.Q5. If we want to learn how to operate the machine, Can you provide it?Yes, we can. We can provide the on line training by video. We also provide free trainingcourse in our company.Q6. Do you provide the onsite service if we needed?Yes. We can provide the onsite service if you needed. But need the customer pay for the transport, hotel, food and 100USD/day.Send to us