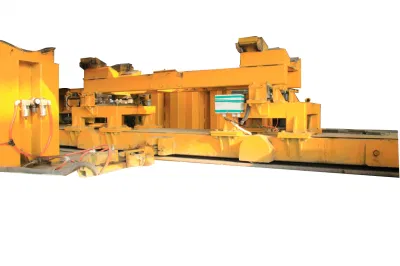

Tangchen Pipe Production Line Standard Export Packing, Container/Bulk Cargo Culvert Price Concrete Precast Machine

This Automatic Concrete Precast Spun Pile/ Electric Pole Production line is used for producing concrete precast spun pil

Basic Info.

| Model NO. | TC100 |

| Application | Industry |

| Type | Pipe Production Line |

| Trade Terms | Ex Works/Fob/CIF |

| Technological Advantage | Our Engineer Is Highly Educated and Experienced |

| Delivery Time | 45 Working Days |

| Power | 380V/50Hz Three-Phase Power Supply |

| Scope of Application | Production of Concrete Spun Pile |

| Transport Package | Standard Export Packing, Container/Bulk Cargo |

| Specification | Φ 300-Φ 600 |

| Trademark | Tangchen |

| Origin | China |

| Production Capacity | 10 Plants/ Year |

Product Description

Tang Chen Machinery is one of the very few Manufacturers in China that can supply complete set of highly automatic production line of prestressed concrete spun pile/ electric utility pole and EPC project. Compared to traditional spun pile/ electric pole production line, this production line has made the manufacturing process less human-dependent. That means higher efficency and lower failure rate.

The production line is consist of 6 major parts: 1. Raw material mixing system, 2.Steel cage making system, 3. Concrete feeding and placing system, 4. Centrifugal shaping system, 5. Conveyor system, 6. Hanging and spread system.

Below is detailed work flow of the production line:Picture show case

Send to us