Storage Management Belt Pallet Rack Access Remote PLC Automatic Automated Feeding Control Detection Line Overhead Mining Handling Warehouse Conveyor System

Basic Info.

| Model NO. | gojon-0001 |

| Type | Packaging Production Line |

| Function | Transport Packaging, Storage and Packaging, Sales Packing |

| Packaging Technology | Shockproof Packaging |

| Application | Drinks, Dairy Products, Cleaning, Detergent, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Seasoning, Hair Care Products |

| Soft and Hardness | Flexible Package |

| Circulation Function | Outer Packing |

| Frequency of Use | Several Packaging |

| Mode of Operation | Packaging of Export Products |

| Electric Parts | Simens, Schneider, Delta |

| Control System | PLC |

| Transport Package | Container |

| Specification | Customzied |

| Trademark | GOJON |

| Origin | Qingdao, China |

| HS Code | 84418090 |

| Production Capacity | 1000sets Per Year |

Product Description

1.Module belt conveyor Short Description

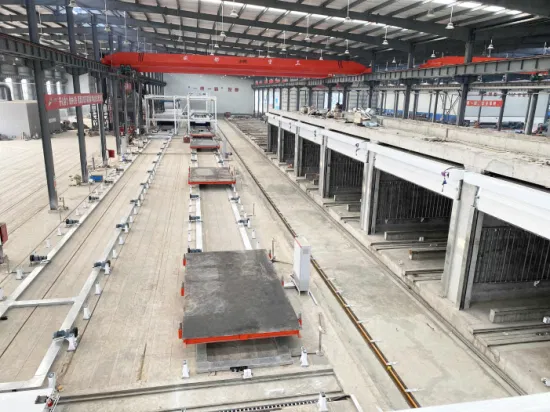

Auto Module Conveyor System is high efficient downstream and processing system for modern corrugated cardboard and carton box factory. Through the layout of the whole plant, a reasonable plan is designed to realize automatic cardboard conveying and reduce manpower and material resources

| Brand | GOJON |

| Product origin | Qingdao,China |

| Size | Customized |

| Delivery time | 30days |

| Supply capacity | 1000sets/month |

Product Catagary:

Detail Picture

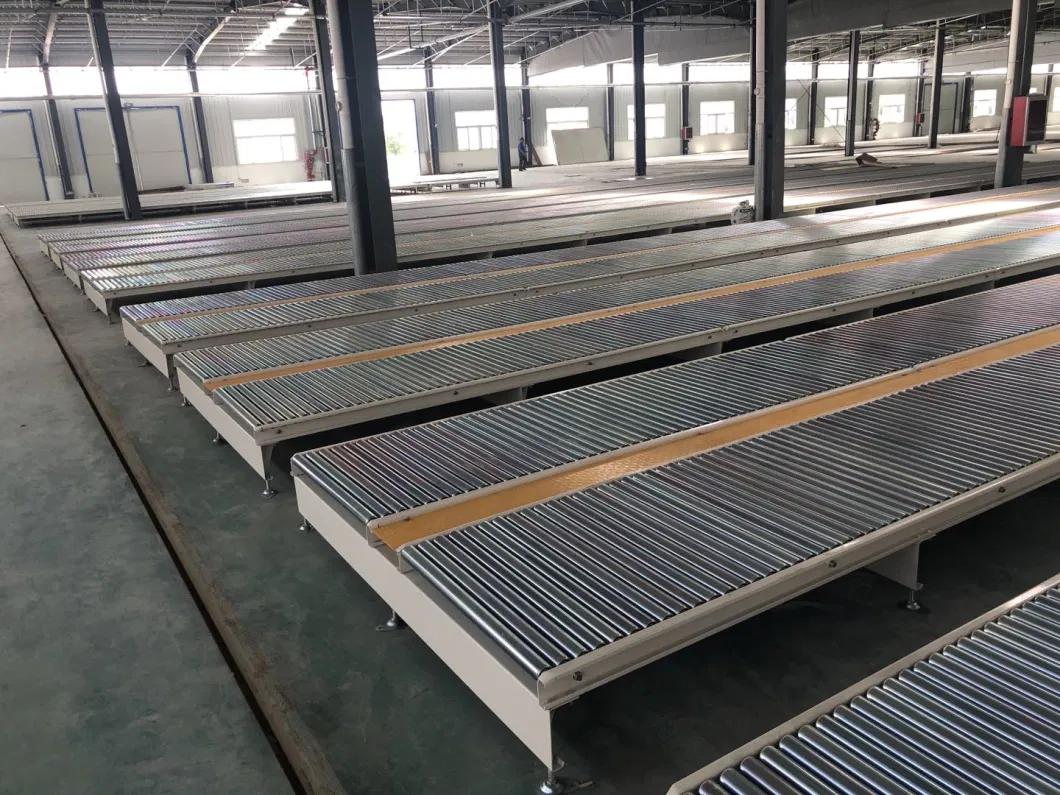

2.Module belt conveyor Technical Parameter:

condition:

| 1 | Control voltage | 24VDC; |

| 2 | Climate Condition | Interior: 10-40°C; |

| 3 | Humidity | an average of 60%; maximum 95%; |

| 4 | Compressed air Pressure | 0.5 ~ 0.7 MPa; |

| 5 | Dew point | + 2 ~ + 10°C (7bar + 2 ~ + 10°C); |

| 6 | Filter | 40μm; |

| 7 | Quality | Oilless airless air; |

spefication:

| 1 | Dimensions | customized |

| 2 | Conveyed belt | imported POM material module network belt, net belt thickness: 12mm |

| 3 | Conveyor belt sprocket | overall processing of PP materials |

| 4 | Conveyor support | composite wooden board |

| 5 | Equipment material | 10T iron plate laser processing |

| 6 | Net belt speed | max 30M / min (inverter control) |

| 7 | Motor Power | 2.2KW Wanxin Brand |

| 8 | Programmable logic controller | SiemenSimens Brand |

| 9 | Inverter | Delta Brand |

| 10 | Low voltage electrical parts | brand |

| 11 | Appearance | Surface static spray |

3.Why you choose our products?

Intelligentized Cardboard Conveyor System:

1. Reducing labor cost

2. Facilitating operation 3. Satisfying the needs of the modern enterprise's production and management

Conveyor System On the Buffer Zonel:

With the optimization of purchase orders and the upgrading of the speed of the line, the existing storage mode can't satisfy the demand of the production capacity. However, GOJON software greatly expands the storage space, lowers the cost of transportation, improves the operating efficiency, ensures the tidiness & orderliness of the workshop and enables the limited storage space to create infinite value.

The Feed In And Feed-Out On The Processing Area:

In response to the constant upgrading of printing machine and die-cutting machine, GOJON conveyor system solved the problems of human handling fatigue and low conveying efficiency, To make processing equipment develop efficient capacity of printing machine and die-cutting machine, realize the intelligent operation on the processing area.

4.FAQ

| 1 | Do you have a minimum order quantity? | Yes, we require all international orders to have an ongoing minimum order quantity. But if you are looking to resell but in much smaller quantities, you can also contact us for further information |

| 2 | Can you supply the relevant documentation? | Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required. |

| 3 | What kinds of payment methods do you accept? | You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L. |

| 4 | What is the product warranty? | We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction |

| 5 | How about the shipping fees? | The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information. |

5.Other Related products

1)Paper roll conveyor system

2) Drive Roller Conveyor

3)Unpower Roller Conveyor

4), Automatic Laminator

5)Automatic Strapping & Wrapping line

6)Semi-Automatic Palletizer

6.Facilities & Capabilities