Precast Concrete Laminated Slab Production Line in China with Good Sale

PRECAST CONCRETE WALL PANEL PRODUCTION LINE The PC production line is used for the production of the panel components su

Basic Info.

| Model NO. | automatic |

| Productivity | 240m²/h |

| Feeding Height | Good |

| Vibrating Amplitude | Other |

| Certification | ISO9001: 2000, CE, ISO |

| Condition | New |

| Color | Customer Demand |

| Transport Package | Good |

| Specification | automatic |

| Trademark | HAIYU |

| Origin | China |

| HS Code | 847480 |

| Production Capacity | 1set/Month |

Product Description

PRECAST CONCRETE WALL PANEL PRODUCTION LINE

This production line including:

1. Central control system

2. Feeding system

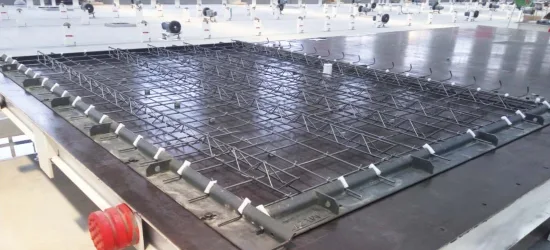

3. Table Pretreatment System

4. Table circulating system

5. Demoulding System

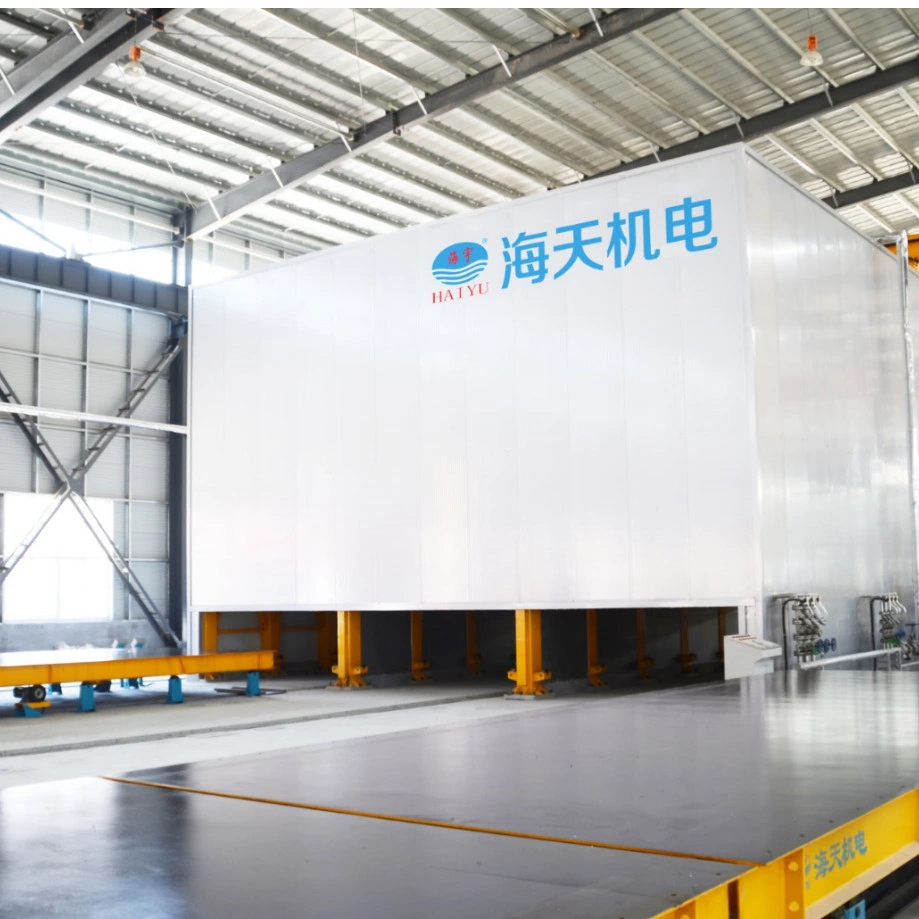

6. Curing System

Central control system

1,The central control system uses the WINCC central computer control system; 2,It can be transferred manually, automatically or semiautomatically; 3, The control system can communicate with the various equipment of the production line to complete the coordinated production of the production line; 4, The fault display, query and alarm functions of the entire production line can be realized; 5, It can not only realize the connection with the ERP system of the component production, but also realize the monitoring of the temperature and humidity of the pre-curing kiln, the multistory steam curing bin and the composite slab, and the automatic data recording, analysis and sorting functions. In addition, it can automatically draw thetemperature control curve and real-time temperature curve and is access to real-time status queries.Feeding system1,Variable frequency adaptive drive. 2,With sloped transport capacity; 3,Hydraulic drive door ; 4,Seamless connection mixing plant and production line. 5,Provide a hand held wireless remote control.

Table Pretreatment System

Table circulating system1, The structure is solid and durable; 2,Effectively control the deformation of the table in order to extend service life through finite element analysis and process methods. Demoulding System1,Adopt the model of hydraulic jack-up side way demoulding; 2,Unique way of security fixes, effectively prevent the Artifacts rollovers;

Curing System1,Adopt low level design, energy consumption; 2,Before and after using lifting doors, automatic induction in and out the moulds; 3,Automatic heating control.

Our Certificate

We supply technical supporting all the time.Our salesman will be online for 24 hours.You can visit us at any time.We supply one year warranty for whole machine.We supply free quick wear parts.We supply low charge continue maintenance when warranty is expired.We supply free training for end-users.

Send to us