Powder Coating Line for Car Wheel Rim Powder Coating System

Basic Info.

| Model NO. | JH-L3 |

| Condition | New |

| Delivery Way | by Sea |

| Application | Spray Powder Coating |

| Delivery Time | 25days |

| Input Voltage | 220V -415V or as Request |

| Transport Package | Carton |

| Specification | JH-L1 |

| Trademark | JINHAI |

| Origin | China |

| HS Code | 8424899990 |

| Production Capacity | 200 Set/Year |

Product Description

Manual Electrostatic Powder Coating Line

Powder Coating Line Features:

1. All of our powder coating lines are customized.2. According to the customer's requirement, such as : size of product, capacity, product's shape, size of workshop for the spray booth and curing oven etc, we will help customer find the best solution of coating system.3. We will provide design draft , production, installation, commissioning and training.Diesel /Gas / Electric Powder Coating Line Processes : loading -pretreatment (degrease & rinse & drying )-powder coating -leveling - curing in oven -cooling -unloading

Techinal Parameters

Name | Design Parameter |

Project name | Spraying powder coating production line |

Workshop | Customer's workshop size ( LXWXH mm) |

Workpiece material | Metal material |

Workpiece size | Customer's products size ( LXWXH mm) |

Max. output | How many pcs per hour or per day |

Type of spraying | Manual |

Heat method | Electric / LPG / Natural Gas / Diesel |

Type of conveyor | Automatic |

Speed of line | According the output |

How to inquiry powder coating line?

You'd better offer the specifications of your workpiece to us.The production process (if you are new on coating, we will give you specialized suggestion of the whole work)The size of the workpiece (including the max length, width, height and weight)The capacity (how many pcs in 8 hours)The available size of your factory (including the length, width and height)The heating power (electricity, natural gas,LPG or diesel oil )How many colors do you need to change every day.The local electricity conditions(_v/_phase/_hz)The any special requirements about the package.Our powder coating system's design and production all according to customer's requirement(capacity, size of product, size of workshop).

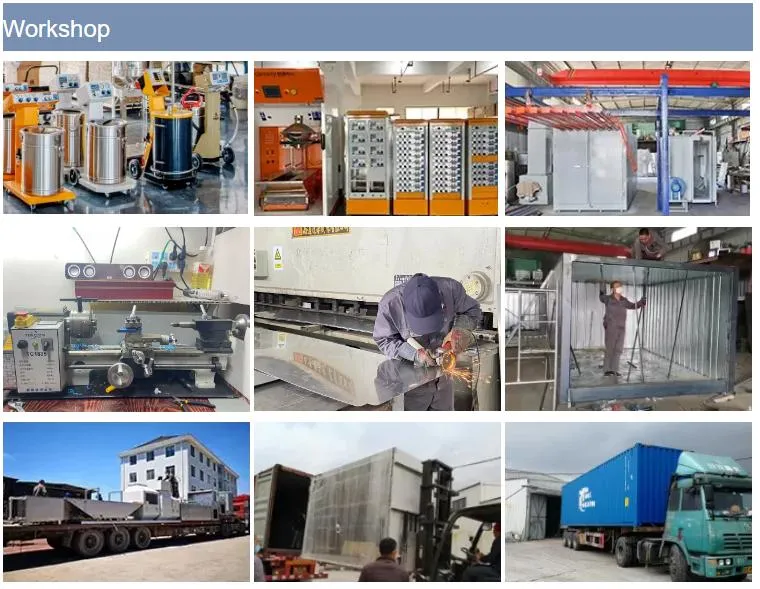

Details Images

Tunnel Spray Booth • No dust spillover, reduce powder waste. • Quick color change. • Easy to clean, save labor time. • Reliable operation and durability. • Beautiful appearance, fine workmanship.Bridge Type Curing Oven• Powder specific design, custom sizes and configurations available.• High quality insulated double wall design and natural gas

or liquefied petroleum gas fuel• Made of high quality galvanized steel construction• Easy access to floor-standing heating systems and exhaust system standards• Can be used for preheating, drying, curing or multi-functional design

A: We are manufacturer which exported to many countries and we are specialized in producing powdercoating equipment more than 10 years in China.

Q2: What about the lead time ?

A: Generally it is 3-5 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to product and quantity.Q3: Can I customized the machines?Yes, we are a professional team for powder coating equipments, Our technician will design for you specially according to your needs and your factory, workpiece etc information.

Q4: Can you do OEM?

A: Yes, the product size can do customized.Q5: How long is the warranty?

A: Our warranty is 12 months.

Q6: Can you install for us?Yes, we can install overseas for you. But the engineers overseas installation cost, round trip air tickets, accommodation, meals and transport charges are on the buyers.