Automatic EPS Precast Wall Panel Machine Lightweight Concrete Panel Slab Machines

Package Size 10.00cm * 30.00cm * 20.00cm Package Gross Weight 20.000kg Introduction to wall panels: 1. Precast cement li

Basic Info.

| Model NO. | YR-G6100 |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Screw Design | Double-Screw |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Application | EPS Wall Panel Production |

| Width | 610mm Special Sizes Need to Be Customized |

| Length | 2440~3600mm Special Sizes Need to Be Customized |

| Finished Board Type | 1. Sandwich Board, with Surface Board 2. Solid Pan |

| Surface Board Types | 1.Calcium Silicate Board 2. Fiber Cement Board 3. |

| Raw Material | There Are Mainly Two Different Types 1. Cement+EPS |

| Capacity | 20,000sqm~800,000sqm Per Year |

| Thickness | 50-250mm Thickness. Special Sizes Need to Be Custo |

| Function | House Building Construction |

| After Sales Service Provided | Video Technical Support |

| Transport Package | Container, Bungee Cord |

| Specification | Panel: 610*2440mm |

| Trademark | Yurui |

| Origin | Shandong, China |

| HS Code | 8474802000 |

| Production Capacity | 200 Sets Per Year |

Packaging & Delivery

Package Size 10.00cm * 30.00cm * 20.00cm Package Gross Weight 20.000kgProduct Description

Introduction to wall panels:

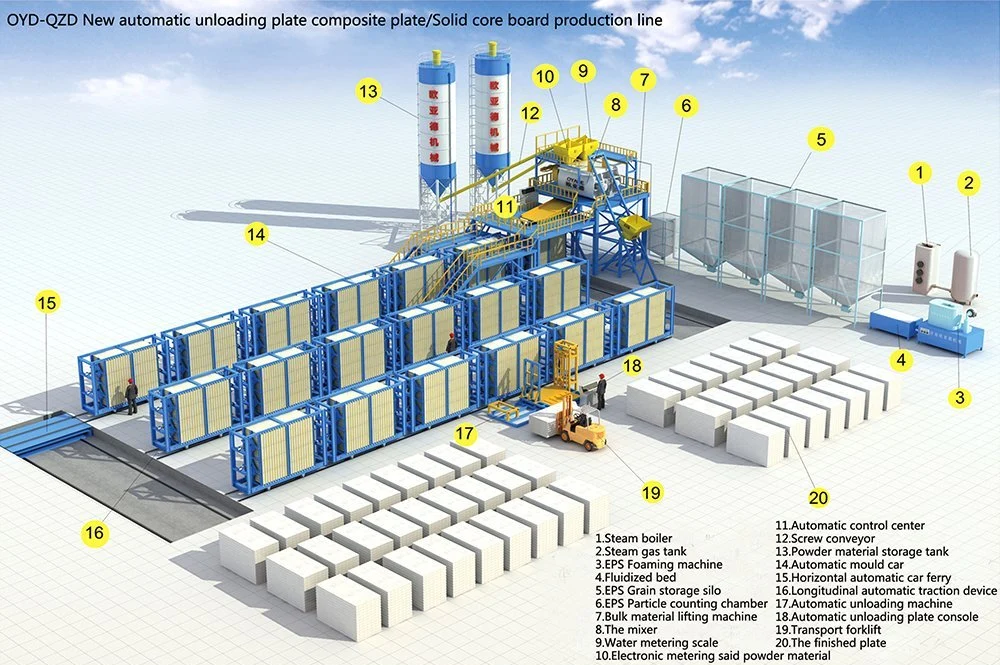

1. Precast cement lightweight wall panel making machine 2. Concrete wall panel machine 3. Eps wall panel machine 4. Composite wall panel machine 5. Hollow core wall panel machineVertical wall panel production line

Vertical wallboard mold car

1.Panel Type: Sandwich wall panel and Solid wal panel2.Panel Size: 2400-3200*610*75- -200mm 5aR:2400- 3200*610*75- 200mm3.Unloading Device: Automatic Unloading Machine

Horizontal Mold Car

1.Panel Type: Hollow core wall panel, Composite wall panel, Solid wall panel.2.Panel Size: 2400-3600*610*75- 200mm.saRv: 2400- 3600*610*75- -200mm3. Demolding Method : Frame Crane/Automatic Unloading Machine.

Finished panel

| Composite wall panelSandwich wall panel | Solid wall panel | Hollow core wall panel |

Unloader

Product Description:

1.Unloading panel: 20pcs /per time 2.Time : 8-10 mins / mold car

3.Number of workers: 2- -3workers

Advantage

1.We have full automatic demolding system to reduce the working strength, this is our patent tchnology, and tis very mature now.2.0ptimize the structural design, choose high strength high quality carbon steel, meet the strict conditions of usage.3.The inverted platform use double hydraulic cylinders to output power, and the platform bears more balanced forces withoutdeformation.4.Original bottom molding beam structure design, automatic hydraulic pressure, let workers operate easily and quickly.

Production Process

Equipment Advantage

1.The structure of the machine is simple and easy to maintain. Extremely low maintenance rate of the consumable parts, and the consumable parts are universal and easy to replace, no specific purchase required.2.The machine runs stably and the production efficiency is very high.3.The whole line is made of 304 stainless steel drum the diameter is 240mm, which is suitable for suitable for magnesium products, durable and easy to clean.4.According to our 23 years ' experience in mgo board field. The automation is the No.1 in China, compare to others could help save 30% labor cost.5.Higher production capacity. Could produce up to 2400 pieces in 10 hours, higher than the industry standard in thisfiled.6.A set of solutions can produce a variety of plates, whether it is the MgO board or the cement board, to meet the needs of different customers and occupy more market shares.

Follow-up Service

Project photo

Engineers went to the UAE, Russia, Qatar, Malaysia, Syria,Ecuador, Uzbekistan, Algeria, the Philippines, India,Cambodia,Mexico and other projects for installation and training cases.

Follow-up services

After the completion of the project, we will continue to provideservices to help customers purchase rawmaterials andaccessories. If there is any problem in the production, we will givecustomers a satisfactory answer within 24 hours.If necessary, wewill arrange engineers to help customers solve the problem onsite.

Company History

OYD group was established in 2008, it has 5 subsidiaries for researching anddevelopment of producing different kinds of products, eps concrete wall panel machine; mgo board production line; hollow glass aluminum spacer; Laser cutting machine,etc.In 2011, Yurui participates Jinan Oyade CNC Machinery Co.,LTD as one shareholder, established OYADE (Shandong) Machinery Equipment Co, Ltd. Mainly responsible for production and exportation of lightweight concrete wall panel production line and mgo board production line.The brand name is OYADE & Yurui.

Association Certificate

Company Products

Any problems please feel free to contact us. Contact person:Carson

Send to us