4000PCS/H High Speed UV Curing Machine for Fully Automatic Screen Printing

Package Size 308.00cm * 195.00cm * 160.00cm Package Gross Weight 596.000kg uv curing machine for Automatic Swing Cylinde

Basic Info.

| Model NO. | TM-UVC-1200L |

| Heating Mode | Radioactive |

| Material Status | Bulk |

| Drying Medium | Air |

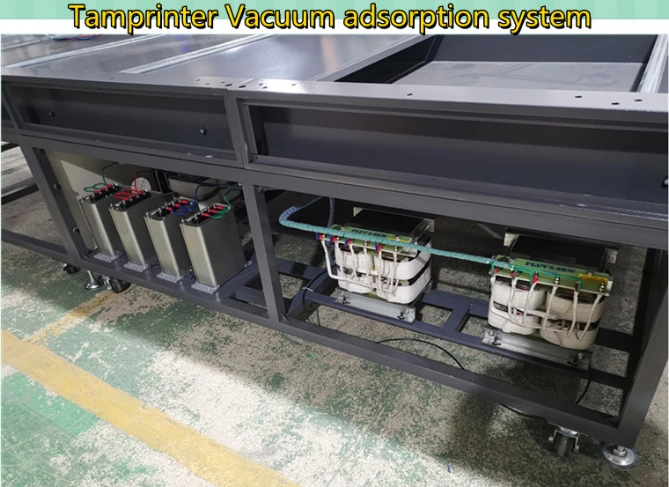

| Operation Pressure | Vacuum |

| Type | Single Layer |

| Speed | 1000-3600 PCS/H |

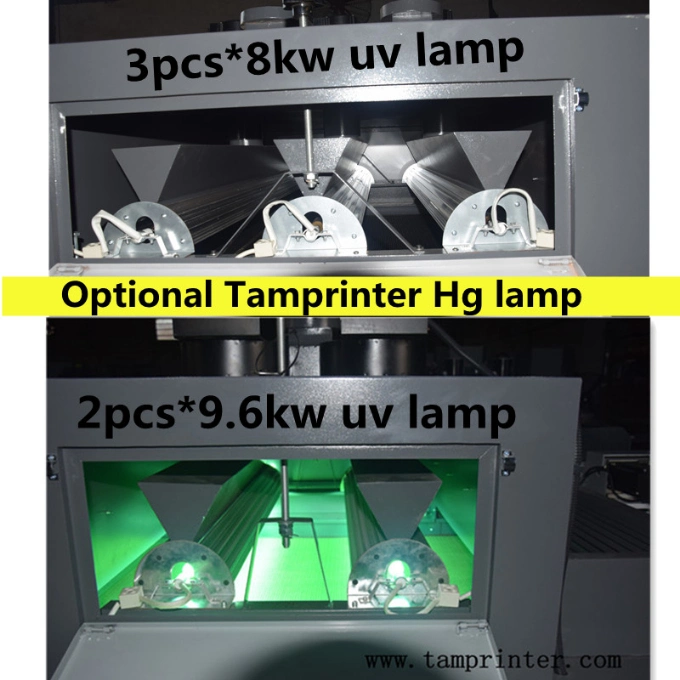

| UV Lamp | 8kwx3PCS |

| Weight | 1150kg |

| Driving Power (W) | 90 |

| Max Paper Size | 1020*720 mm |

| Sheet Thickness | 100-350 G/M2 |

| Transport Belt Width | 1180(mm) |

| Transport Package | Plywood Case |

| Specification | CE |

| Trademark | Tamprinter |

| Origin | China |

| HS Code | 8442309000 |

| Production Capacity | 30sets/Month |

Packaging & Delivery

Package Size 308.00cm * 195.00cm * 160.00cm Package Gross Weight 596.000kgProduct Description

uv curing machine for Automatic Swing Cylinder Screen Printing parameters:| Model | TM-UVc- 750L | TM-UVc- 900L | TM-UVC-1200L |

| Transport belt width | 730(mm) | 880(mm) | 1180(mm) |

| Max Paper Size | 720*520 mm | 780*540 mm | 1020*720 mm |

| Sheet thickness | 100-350 g/m2 | 100-350 g/m2 | 100-350 g/m2 |

| UV lamp | 8KW X 3pcs | 8KW X 3pcs | 8KW X 3pcs |

| Speed | 600-3600 pcs/h | 1000-3600 pcs/h | 1000-3600 pcs/h |

| Driving Power (W): | 90 | 90 | 90 |

| weight | 717kg | 866kg | 1150kg |

| power | 3P4N 50/60Hz 380V | 3P4N 50/60Hz 380V | 3P4N 50/60Hz 380V |

| dimension | 4090*1110*1600 mm | 4090*1260*1610 mm | 4090*1560*1620 mm |

before buy pls answer follow question if you would like to buy right machine buy machine use in your factory or your customer factory?

uv machine for

1, Automatic Swing Cylinder Screen Printing

2, offset print

3, sheet Screen Printing

4, 3d spot uv machine

which?Different printing speeds correspond to different numbers and power of lamps, generally corresponding to automatic screen printing machines, with different specifications 2*5.6kw, 3*5.6kw, 3*8kw, 3*9.6kw

1,

Do you have your own forwarder in China? Or do you have a customs clearance agent? Do you have import rights and import experience?

2,

Considering that the freight is too expensive, if it does not affect the use function, it is recommended to buy a machine with a standard length of 2.5 meters instead of 3 meters.

3,

Do you need an additional clamshell conveyor bridge to connect to an automated printer? I will express this function later with a video.

Some customers need an automatic stacker.

Considering that the temperature inside the cranial cavity of the ultraviolet machine is 50-80 degrees Celsius, it will make the smooth paper stick together. Usually, a cooling system is added at the end of the ultraviolet machine, and then it is automatically stacked.

UV inks have many effects, do you only dry the varnish? Or is it the wrinkles, the ice, the effects of the snow?

factory OEM &ODM Special effect uv machine

Need other consumables?

Send to us